Powered by FAW 4DW91-29D Engine

Coupled to a single bearing, self-excited, brushless AVR controlled alternator

Deepsea Manual / AMF Control Panel.

Integrated ATS (Auto Transfer Switch).

Configured with 3 pole MCCB.

Side panel cable entry points.

Anti Vibrations Mounts Coupled between engine / alternator and base frame.

Wiring to IEC standard.

Heavy duty modular Powder Coated Mild Sound Attenuated Canopy which will not deform when entire structure is lifted.

Mild Steel Residential exhaust silencer asbestos lagged with Stainless Steel below.

Heavy duty fabricated Powder Coated steel baseframe with integrated day fuel tank including filler / strainer and fuel sender.

Central lifting points and forklift holes are provided to easily manoeuvre the genset into installation position.

Full load test is conducted at 50%,75% & 100% as well as comprehensive FAT (Factory Acceptance Testing).

A full set of operation and maintenance manuals and circuit wiring diagrams are supplied with the unit.

Power Factor: 4 Pole Partner alternators are designed to operate between 0.8 and 1 power factor. The alternator will be de-rated when operating below 0.8 power factor.

Rating: The rating is at Sea Level and deration of 5 % – 10% should be allowed for if the unit operates at any altitude higher than 1500MASL (Consideration should be given as to whether or not the engine is Turbo or naturally aspirated)

VAC: 380-400-415V/220-230-240V (50Hz)

Prime Power(PRP):Applicable for supplying power to varying electrical load for unlimited hours. Prime Power (PRP) is in accordance with ISO 8528. Ten percent overload capability is available in accordance with ISO 3046, AS 2789, DIN 6271 and BS 5514.

Emergency Standby Power (ESP): Applicable for supplying power to varying electrical load for the duration of power interruption of a reliable utility source. Emergency Standby Power(ESP) is in accordance with ISO 8528. Fuel Stop power in accordance with ISO3046, AS 2789, DIN 6271 and BS 5514.

Engine Data

Manufacturer: FAW

Model: 4DW91-29D

Engine Speed: 1500rpm

Prime power: 21KW/28HP

Standby power: 23KW/30HP

Type: 4 cycle, In-line,4-cylinder

Cooling: Water – cooled

Aspiration: Naturally Aspirated

Displacement: 2.54L

Cylinder Bore* Stroke: 90mm×100mm

Cylinder quantity: 4

Compression ratio: 17:1

Minimum Full Load Speed: 1500rpm

Direction and rotation of flywheel: Anticlockwise

Governing: Mechanical

Cooling System

Coolant capacity-engine only: 6L

Thermostat adjusting temperature (range): 83-95℃

Max. coolant temp. permitted_standby: 104℃

Engine Weight: 220 kg

Alternator Data

Model: DAC 184J

Output power: 20 Kva

Rated Current 0.8PF: 86A Per Phase

AVR model: SX460

Phase and connection: 1 Phase 2 Wire

Power factor(Cos Phi): 0.8

Exciter Stator Resistance: 20 Ohms at 22℃

Maximum Overspeed: 2250 Rev/Min

Control System: Self Excited

Insulation class: H

Degree of protection: IP23

Voltage regulation: ±1.0%

Winding Leads: 12

Winding Pitch: Two Thirds

Waveform Distortion: No Load<1.5% Non-Distorting Balanced Linear Load<5.0%

Stator Winding: Double layer Concentric

Bearing: Single

Exciter Rotor Resistance: 0.091 Ohms PER PHASE at 22℃

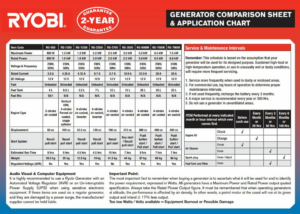

Fuel Consumption @ Various Loads

50% of prime power: 3 LPH

75% of prime power: 4.5 LPH

100% of prime power: 6 LPH

Sound Attenuated Canopy – SAT

The Sound Attenuated Canopy which is produced by Plasma and CNC Turrets not only meets with residential sound control requirements but also ensures the correct cooling aeration required for normal operation. Gensets can be installed in the open air to save space.

Modular design for ease of maintenance and access.

Special high-temperature flame-retardant sound insulation foam.

Slap-up hinge and door handle.

Mild Steel Steel Plate with a powder coated surface finish is utilised for the construction of the upper canopy.

Soundproof foam varies between 40mm to 100mm depending on the degree of attenuation required.

Standard Attenuation Noise Level: 75~80dB within 1m; 72~75dB within 7m.

The Silencer is installed inside the soundproof canopy within a specially manufactured firewall compartment.

The control panel is installed inside the canopy and has a set mounted ATS

Our AMF control panel uses a Deep Sea control module. The Module is an Automatic Mains Fail controller for genset applications. The AMF panel is used where the local utility mains supply is backed up by an appropriately sized generating set. The AMF panel monitors the local mains supply; if this supply should fail, or fall outside pre-set limits the AMF panel will control the pre-heating, fuel solenoid and starting of the generating set either through relays and contacts or via engine ECU if available. The control panel is equipped as below:

Auto Mains Failure Control Panel:

DeepSea 4520 Electronic Controller with Automatic Transfer Switch

Emergency Stop Push Button

Static Battery Charger.

Four-Pole Electronically & Mechanically Interlocked ATS.

DSE 4520 AMF Controller Key Features

This module is used to monitor mains supply and automatically start the genset

Shutdown Alarms

Stop/Rest – Manual – Auto – Test – Start Functionality.

LCD Display Metering

Mains Volts (L-L / L-N)

Generator Amps (L1, L2, L)

Generator Frequency

Engine Run Hours

Plant Battery Voltage

Engine Oil Pressure (PSI & Bar)

Engine Speed (RPM)

Engine Temperature (Degrees Celsius)

Shutdowns & Faults

Under/Over Speed

Failed to start / stop

High Engine Temperature

Low Oil Pressure

Charge Fail

Under/Over Generator Volts & Frequency

Under/Over Mains Volts

Emergency Stop

Reviews

There are no reviews yet.